372 kb

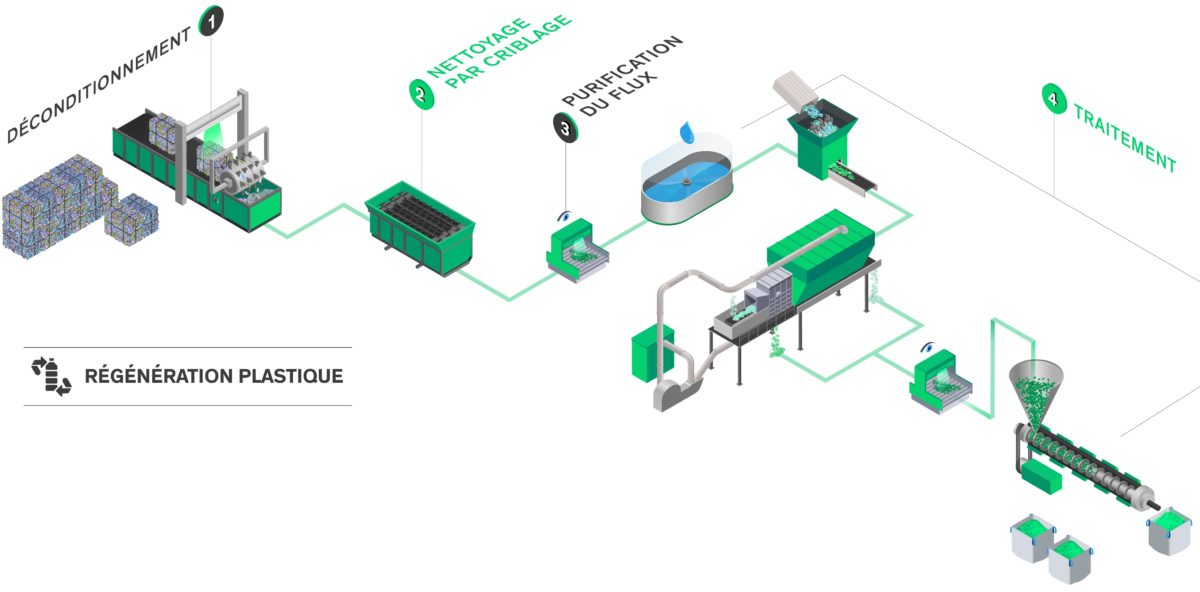

Régénération plastique

Une question ?

Un projet ?

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet consectetur.

Pellentesque non nec morbi scelerisque diam.

Vous cherchez à optimiser vos performances de tri ou de valorisation ?

Vous cherchez à optimiser vos performances de tri ou de valorisation ?

Vous cherchez à optimiser vos performances de tri ou de valorisation ?