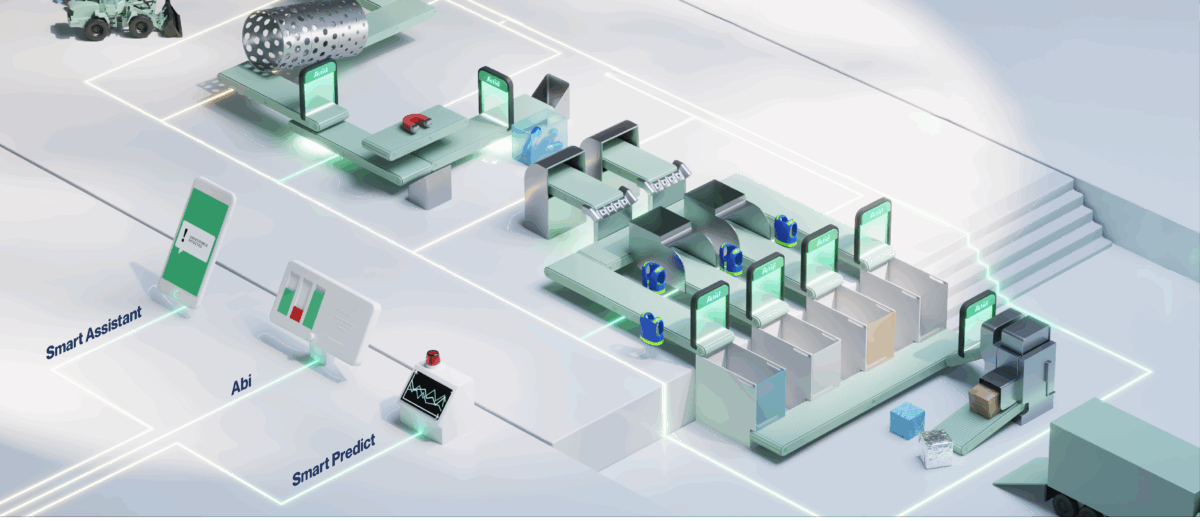

Facilitates supervision and decision-making in the short, medium, and long term.

Operating assistance

Operating assistance solutions

These innovative tools help staff with day-to-day management, facilitate decision-making and alert them to impending problems.

Smart predict

Detect deviations before they occur

Smart assistant

Instantly alert operators to detected risks

ABI

Control process performance

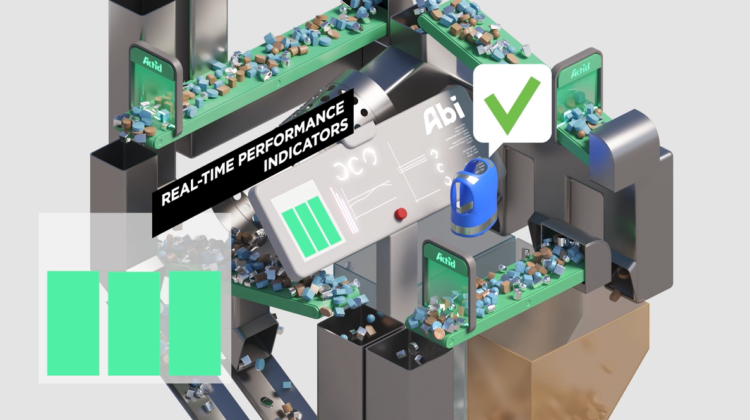

ABI : managing performance

ABI collects data from your equipment and provides you with a clear view of the status of your production, in real time.

ABI contrasts this data and analyses it in order to :

- take preventive action and limit line stoppages

- optimise your line management and make the right decisions

ABI allows you to :

- improve the performance of the sorting centre

- reduce operating costs

- improve production quality

- save time and gain peace of mind

Overview of process performance

Alarms and priority levels for line incidents

Status of machinery and monitoring of deviations

Classification and analysis of causes of failure and recurrences

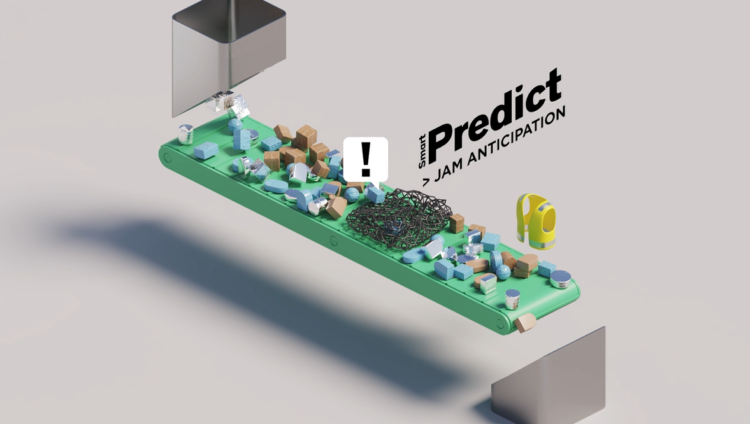

Smart Predict

Smart Predict is a predictive blockage formation detection system, based on a Machine Learning algorithm. If a forming blockage is detected, Smart Predict instantly sends an alert to the field operator so that they can take immediate action on the process.

For the operator, this system improves the availability of the sorting line and the quality of the materials sorted.

Reduced number of stoppages due to blockages

Reduced duration of each stoppage due to a blockage

Increased line availability

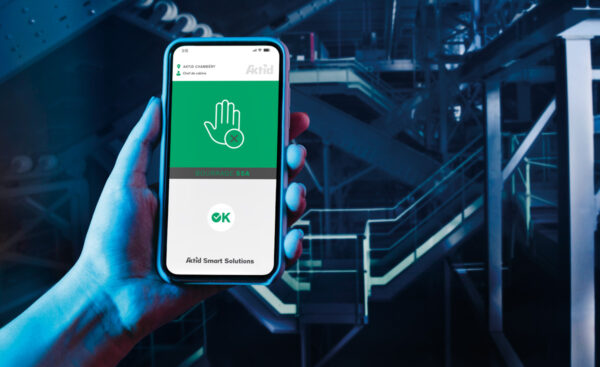

Smart Assistant

Blockage forming alert

Unwanted objects detected alert

Equipment failure alert

© Aktid

Testimony

“Our field operators were very quick to adopt Smart Assistant. The alerts are reliable and come sufficiently in advance to give them time to act. And the operational gains are considerable! Our downtime due to blockages has fallen by more than 30%! ”

M.B.

Operator at a selective collection sorting centre