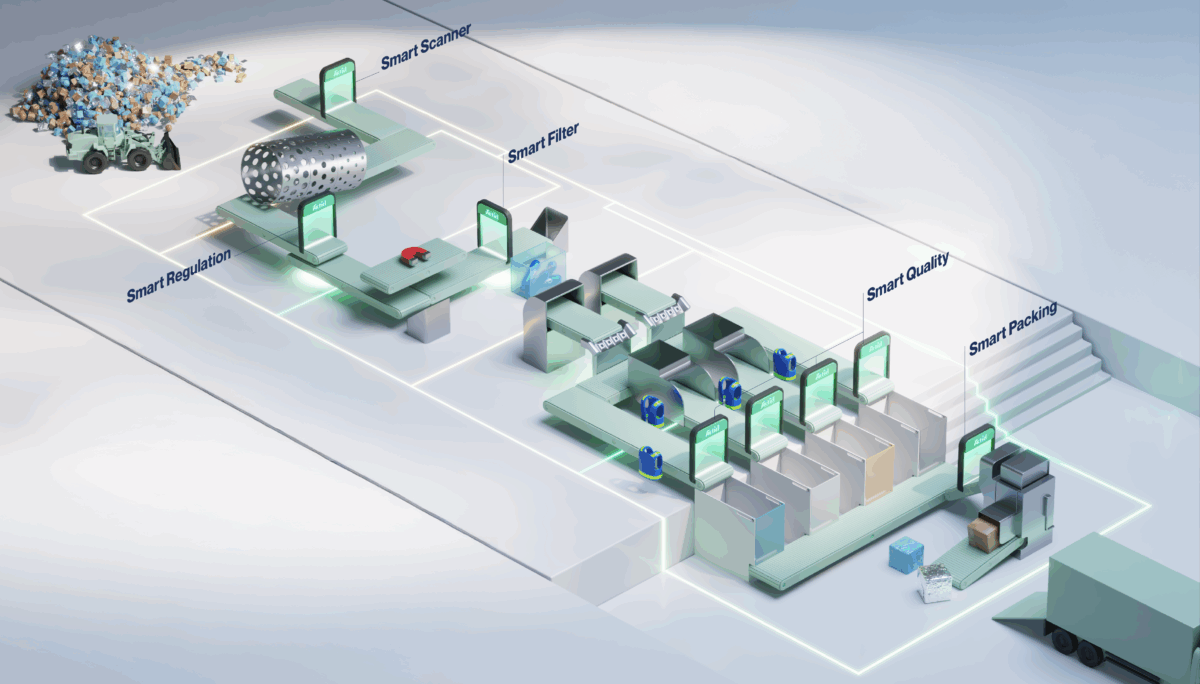

Optimization of operation during a specific phase.

Local control

Local control solutions :

These solutions, positioned at strategic points in the process, control and optimise the operation of the equipment in their zone.

Smart Scanner

Optimize the process from the loading stage

Smart Regulation

Ensure a consistent material flow

Smart Quality

Control the process through quality monitoring

Smart Packing

Determine the optimal discharge scenario

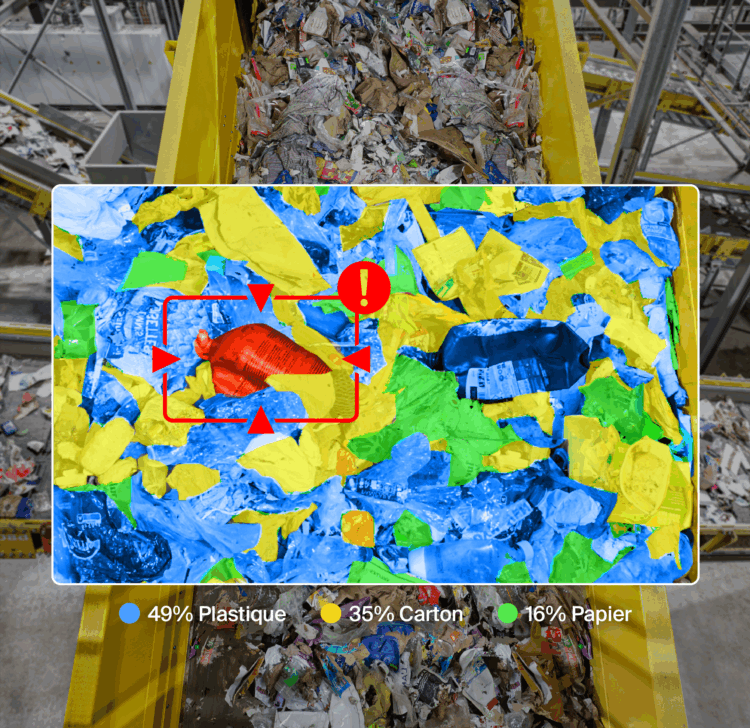

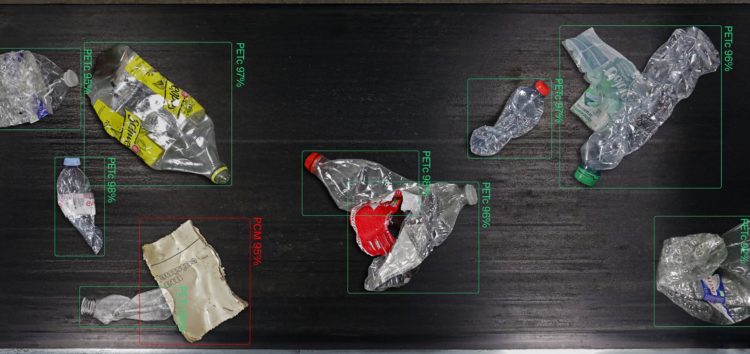

Smart Scanner :

Optimise the process from the moment the line is loaded

Smart scanner continuously analyzes the flow to maintain maximum throughput while ensuring optimum quality.

Smart Scanner characterizes the deposit :

The optical analysis function, combined with an artificial intelligence algorithm, triggers the operations required to ensure controlled operation of the line loading :

- Density control of the feed hopper

- Automated classification of the inflow

- Detection of unwanted objects and notification to operators

Increased line availability rate

Reduced blockages

Availability of KPIs on incoming material composition

Compensation for loading irregularities

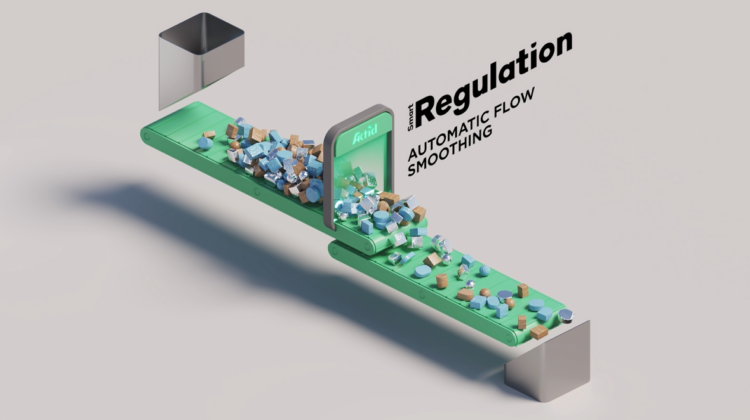

Smart Regulation

Ensure a consistent flow of materials

Smart Regulation is an automated throughput regulation system, positioned at the entrance to the line, to ensure a constant and regular flow of waste through the line.

This Aktid innovation increases the productivity of the process and ensures control over the quality of the sorted product.

Improved line availability rate

Limited blockages

Better product quality

Compensates for irregularities in feed loading

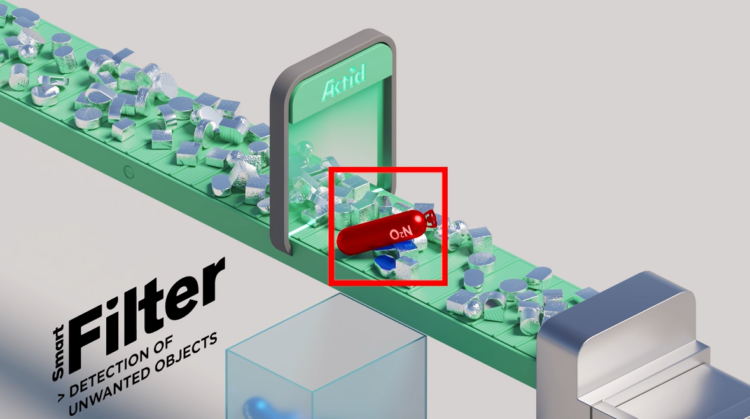

Smart Filter

Protect the process from damage to the packaging press

Smart Filter is an Artificial Intelligence-based detection system for extracting unwanted objects from the steel flow.

The aim of this solution is to extract elements that may :

- Result in a poorer sorting quality

- Damage the packaging press

- Negatively affect the recycling process

Improved line availability rate

Better product quality

Reduced maintenance costs for the packing press

Reduced risks associated with explosions

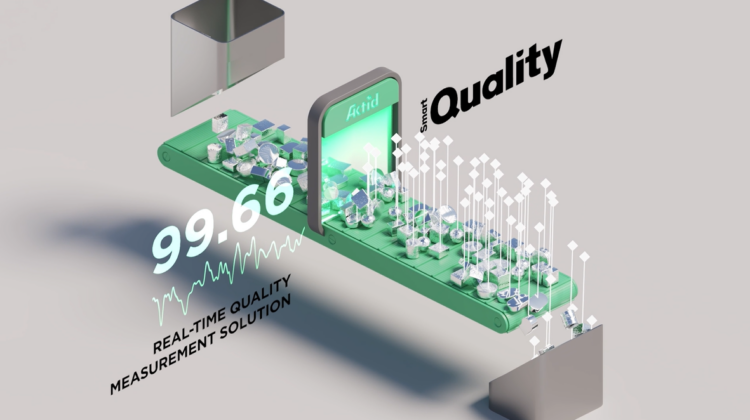

Smart Quality

Quality approach to managing the process

Smart Quality is a flow quality analysis system at the process output, using Artificial Intelligence mechanisms. This solution allows you to :

- Determine in real time the purity rate of waste flows leaving the cabin

- Analyse changes in the purity rate in the medium term

Maintain a high purity rate

Demonstrate the level of performance of the installation.

Example: performance reports

Avoid unforeseen costs.

Example: downgrading of materials, supplier returns

Smart Packing

Determine the optimal emptying scenario

Smart Packing is an automatic silo emptying and baling system that optimises the material packaging process for selective collection sorting centres.

Based on all the data it collects, Smart Packing determines the optimal emptying cycle and controls all the packaging equipment (silos, belts, balers) accordingly.

Significant time savings for staff

Eliminate line stoppages due to full silos

Optimises lorry loading (control of the size and weight of the bales)

Increases line availability by optimizing use of the baler