New Chambéry sorting center: a showcase site and a laboratory for next-generation sorting

A structuring project at territorial level

The new Chambéry sorting center optimizes the recovery of packaging waste from 17 local authorities, representing a population catchment area of approximately 850,000 inhabitants. It is designed to process nearly 40,000 tonnes of selectively collected waste per year, coming from territories with diverse profiles (urban and rural areas, as well as winter sports resorts).

This project is part of a progressive approach undertaken by Savoie Déchets: following the revamping of the former sorting center in 2022, aimed at quickly responding to the extension of sorting guidelines, the construction of a new large-scale industrial facility has made it possible to sustainably secure the territory’s processing capacity.

A sorting center designed to meet high performance requirements

Awarded to a consortium led by Aktid, the design-and-build contract for the new sorting center sets demanding technical targets:

- 12 recyclable material streams produced

- an average throughput of 13 tonnes per hour

- an availability rate of 92%

- a capture rate of 95%

- and less than 15% of recoverable materials in the rejects

The processed waste stream also presents specific regional characteristics, with the presence of atypical undesirable items (notably end-of-life skis), requiring enhanced equipment robustness and a process design adapted to these constraints.

A robust and scalable industrial process

The sorting center is based on a process designed to combine performance, safety and ease of operation. The installation is organized around two separate buildings—one dedicated to reception and conditioning, the other to the process—set more than ten meters apart to limit any risk of fire spread. All buildings are equipped with sprinklers and incorporate reinforced fire-prevention systems.

Waste is received in five storage bays before feeding a 70 m³ hopper and then the sorting line. The process begins with a 14-meter trommel, followed by mechanical and ballistic separation stages. Aktid has notably developed new in-house ballistic screens, offering doubled capacity, easier maintenance in a standing position, and reduced energy consumption.

Material separation is then ensured by a set of 12 optical sorters, complemented by specific equipment such as the Aktid Film Extract, designed to improve the quality of plastic streams.

Smart Solutions: improving plant performance

The Chambéry site serves as a true experimentation ground for Aktid Smart Solutions. The process is controlled by ABI (Aktid Business Intelligence), which centralizes production data and provides the operator with a comprehensive, real-time view of the plant’s performance.

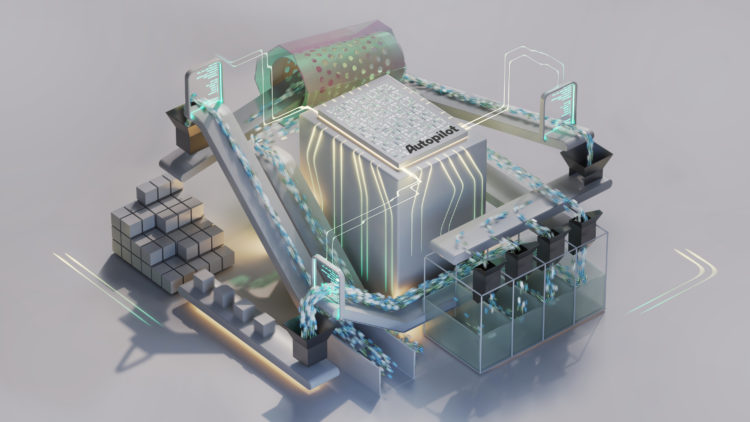

Smart Regulation solutions ensure automatic flow control across the entire line, guaranteeing consistent equipment feeding and improved working conditions in the sorting cabins. The new ballistic screens are also preconfigured to be managed by Autopilot, enabling dynamic adjustment of their settings according to the nature of the incoming waste stream.

Chambéry: a showcase for the sorting center of tomorrow

The Chambéry sorting center is set to become a full-scale laboratory for Aktid’s innovations. Aktid will equip the process with its entire range of Aktid Smart Solutions, including a Smart Scanner to analyze and optimize line feeding, as well as Smart Quality systems installed after manual sorting cabins to measure the purity rate of each sorted stream in real time. As early as this year, Aktid will also deploy Autopilot at the Savoie Déchets site.

Based on data from the Smart Solutions and from the equipment itself, Autopilot will adjust the settings of each piece of equipment in real time, ensuring that the entire process operates continuously at optimal performance.

The Savoie Déchets sorting center is on track to become the first Autopilot-enabled sorting center and a true sorting center of the future.