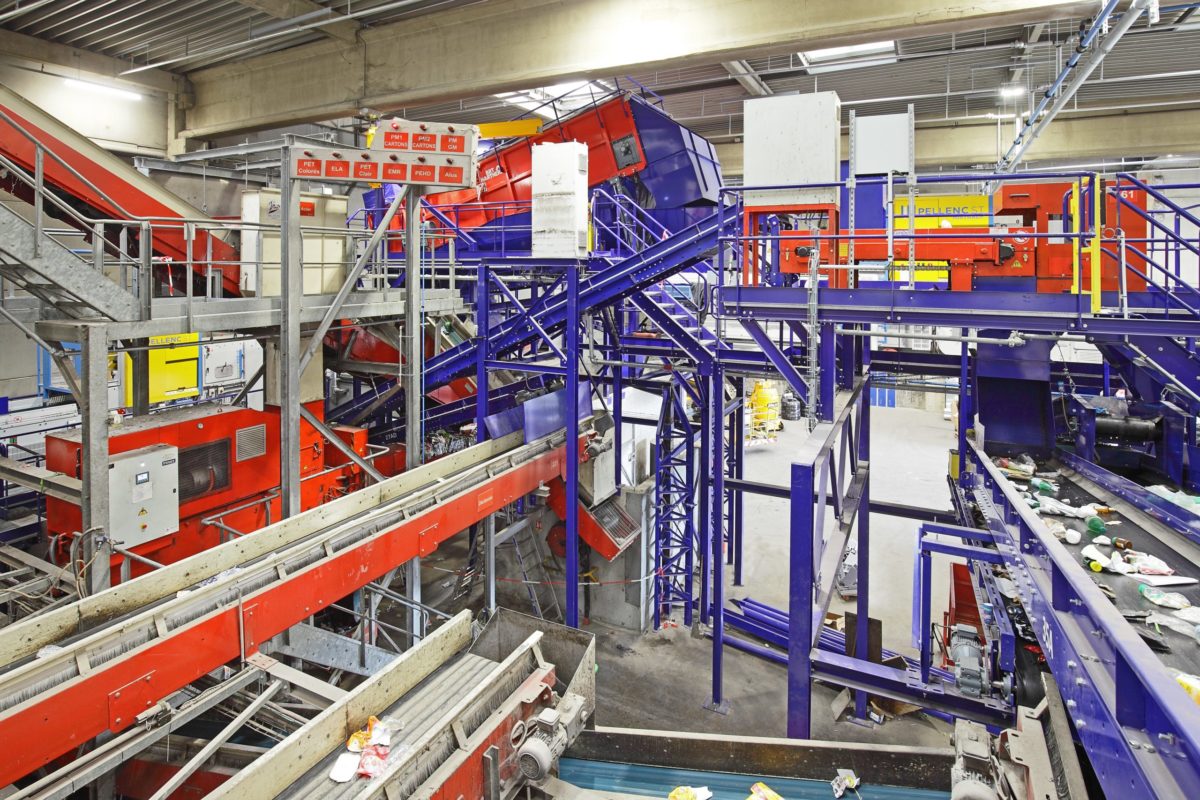

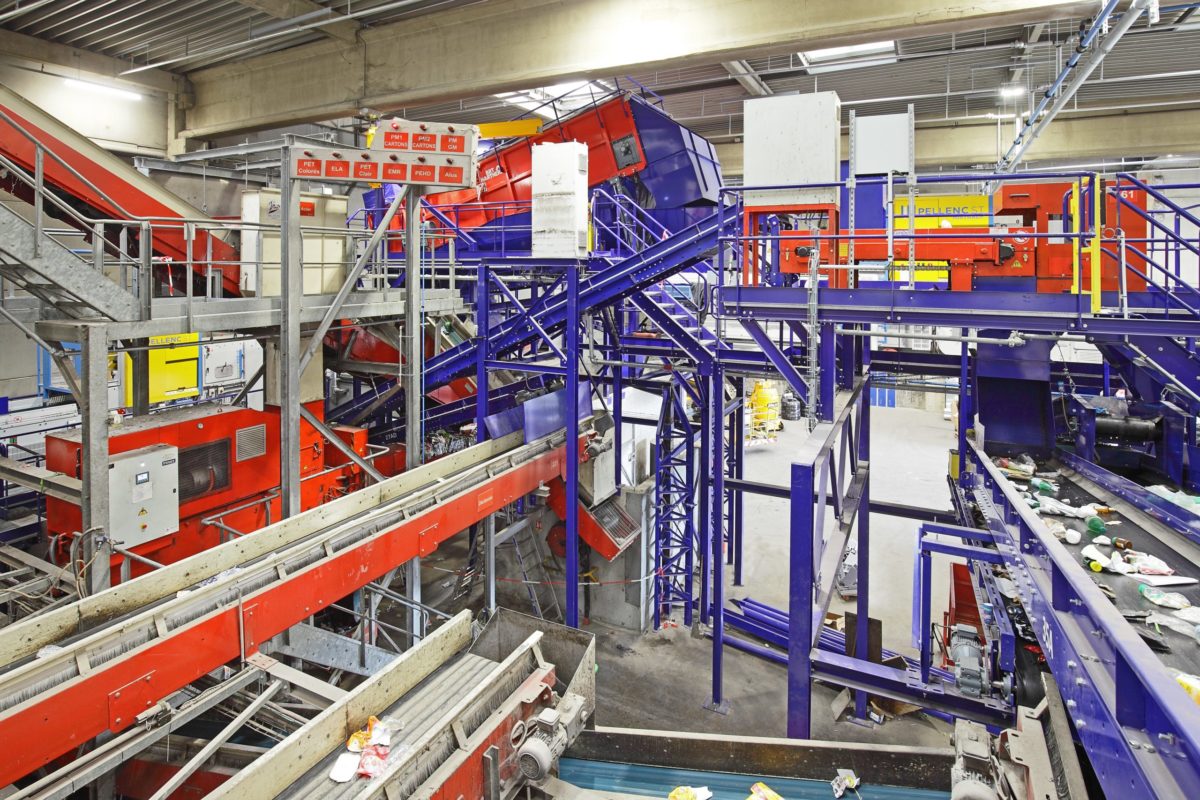

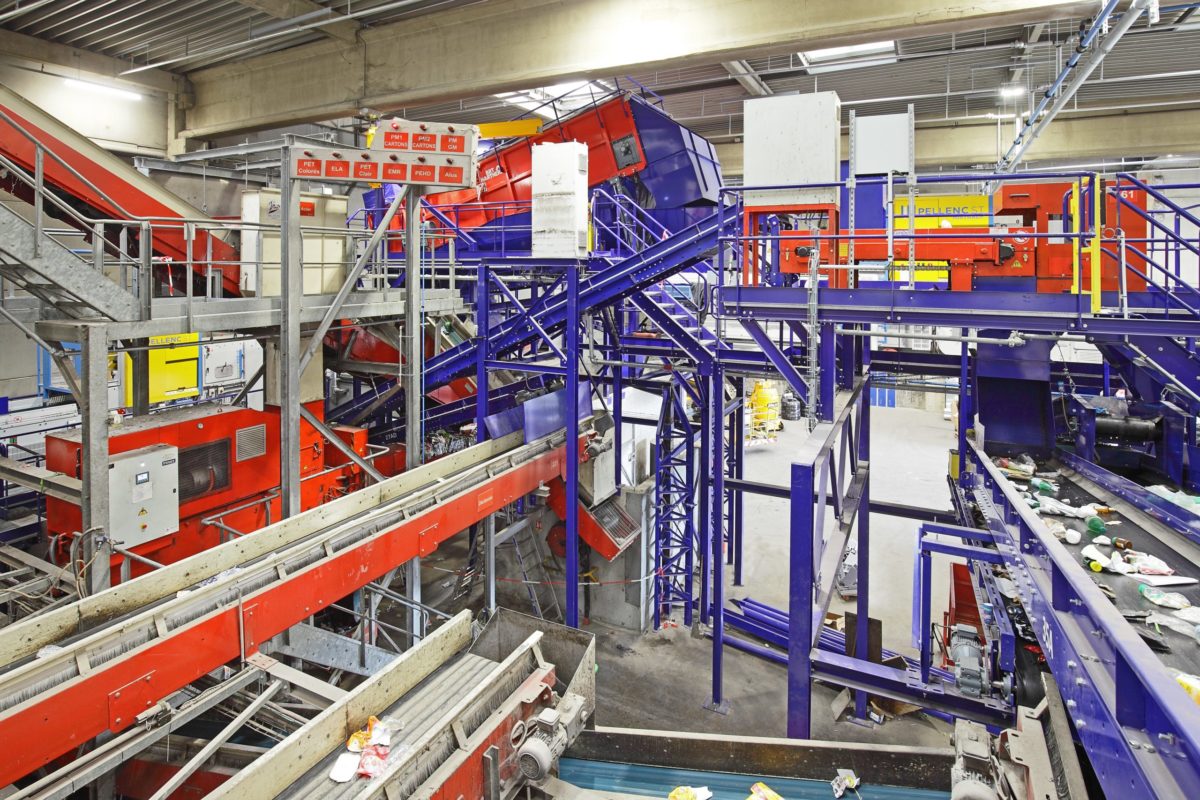

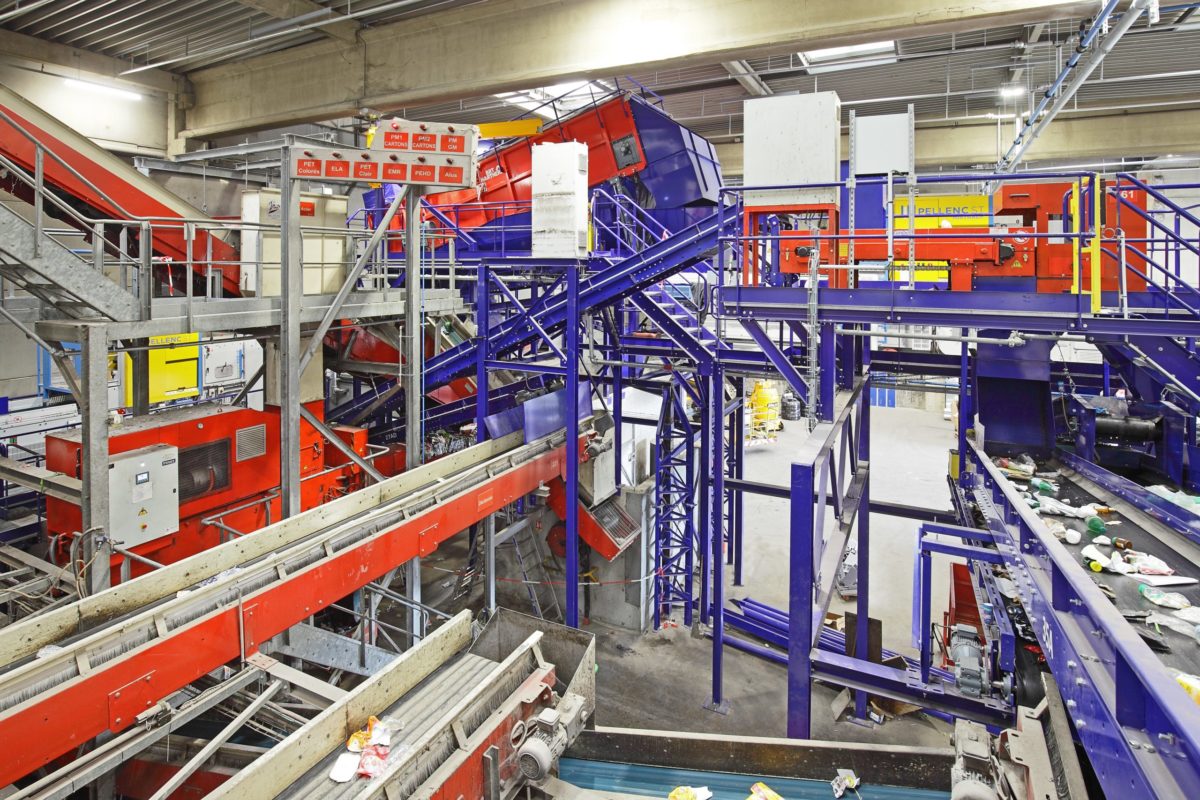

Revamping of a packaging materials – Materials Recovery Facility (MRF)

258 kb

TRIVALO 63

Revamping of a packaging materials – Materials Recovery Facility (MRF)