What are dry recyclable materials ?

Dry recyclable materials comprise all of the waste that households have pre-sorted and deposited in the selective sorting bins or at the dedicated voluntary drop-off points. This recyclable waste consists of paper, cardboard, aluminium, metal packaging and the various types of plastic that compose our packaging, such as PET, PE/PP, HDPE, etc.

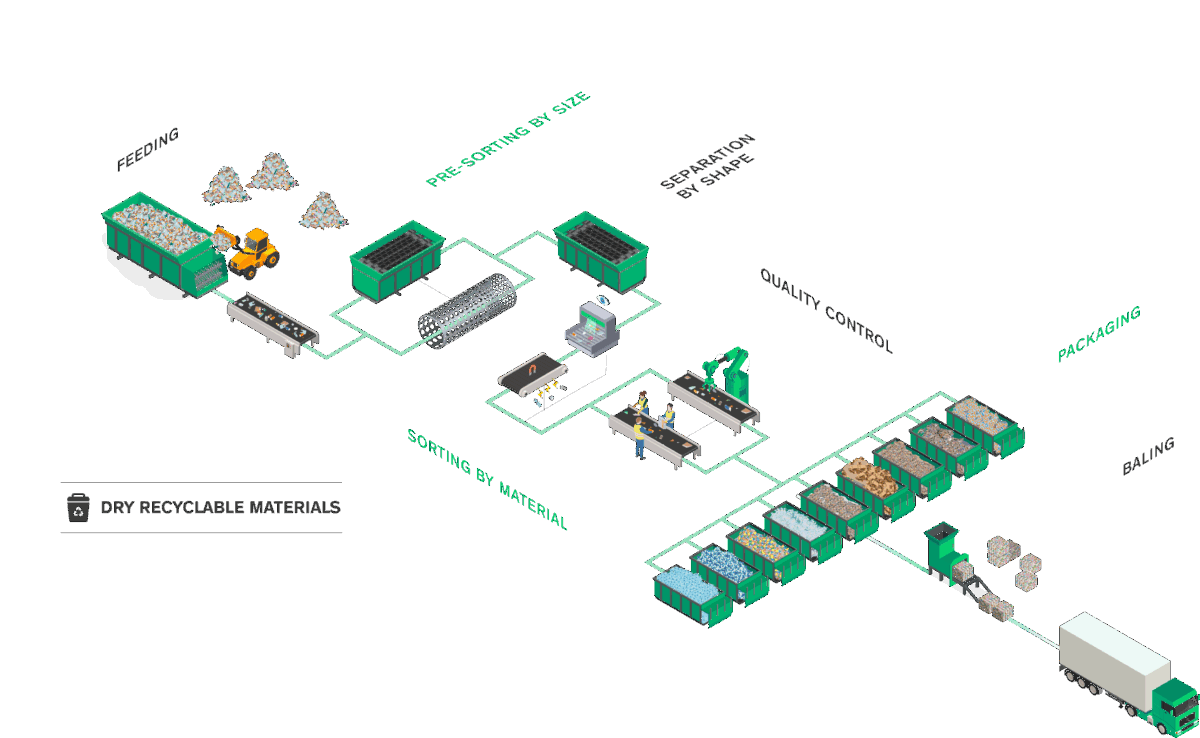

The waste in these yellow rubbish bins is collected separately from household waste and taken to a sorting centre. In order for this waste to be recycled, it must first be sorted to achieve a sufficient level of purity for it to be processed into a raw material.